Pointe Shoes

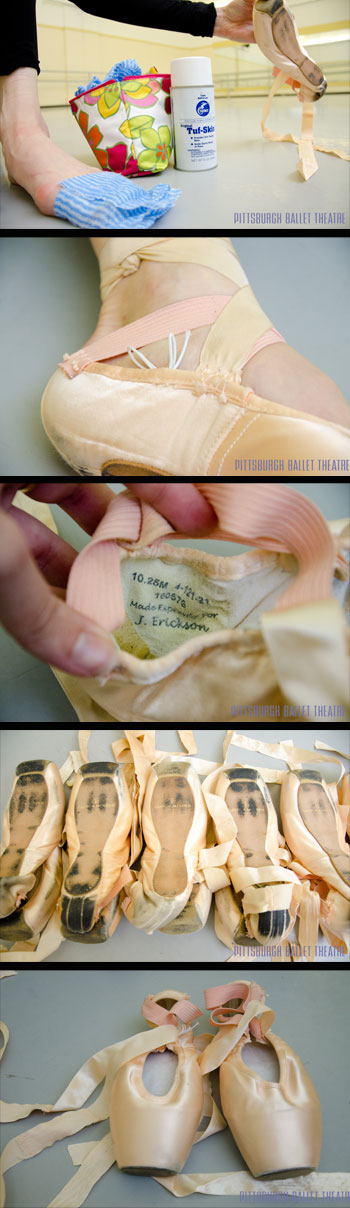

The Perfect Fit: Julia Erickson’s Pointe Shoe Process

A dazzling pointe shoe takes the place of the traditional glass slipper when PBT’s Prince searches fair and wide for his perfect match. Even outside the fairytale, finding the perfect pointe shoe fit is a Cinderella story unto itself in the reality of a professional ballerina.

When a ballerina first unwraps a pair of brand-new pointe shoes, they won’t remain that way for long. To the untrained eye, it seems absurd to sew, step on and scratch a flawless new pair of pink satin pointe shoes. But, achieving that perfect fit is an incredibly individualized process that often entails sewing, super glue, specifications and even arm strength.

Here, PBT Principal Julia Erickson shares her tricks for perfecting her pointe shoes.

Julia Erickson, PBT Principal Dancer

Current Pointe Shoe Style: Gaynor Minden, Size 10.24m

First Pair of Pointe Shoes: Bloch Supremas

Design Customizations:

-Reinforcing material sewn into arch of shoe

-Sides cut down (to show the shape of the foot)

Pointe Shoe Rotation: 6-8 pairs of prepared shoes with few retirees due to the durability of the shoe

Tools of the Trade: blue handy wipes, elasticized ribbons, toe spacers

Since PBT Principal Julia Erickson switched to Gaynor Minden, she’s dropped significant time from her pointe shoe prep. And, amid an average eight-hour rehearsal day, every minute is precious.

The ballet equivalent of high-tech equipment, Gaynor Minden uses high-tech polymers to construct the shank (sole of the shoe) and box (hard toe of the shoe) as opposed to the layers of papers, fabrics and glue traditionally used to handcraft pointe shoes.

“I think that these are the evolution (of pointe shoes). Gaynors distribute the support, because of the material….Honestly, I think these extend the life of my career,” said Erickson, adding that the shoes provide additional support and comfort for chronic arthritis in her second metatarsal.

With her previous style of shoes, Erickson used to cut the inside shank (or sole) at the arch of her foot, but her new style doesn’t require that sort of tailoring. Sewing on new ribbons and loosening them up with some light bending sums up of the extent of hercurrent pointe shoe prep.

“You don’t cut it; it’s designed to bend, she said. “These are very consistently made.”

As a Gaynor Minden artist, Erickson now helps advocate the brand, a fairly new trend in pointe shoe styles, for other professional dancers.

“I like dancing in them, and they’re so much easier,” Erickson said. “(As professional ballerinas) we are very sensitive to our shoe needs, and we are very particular, kind of Princess and the Pea style….The best shoes are the pair that you’re not thinking about…they’re a vehicle for you to be the best dancer you can be.”

The Perfect Fit: Christine Schwaner’s Pointe Shoe Process

A dazzling pointe shoe takes the place of the traditional glass slipper when PBT’s prince searches fair and wide for his perfect match. Even outside the fairytale, finding the perfect pointe shoe fit is a Cinderella story unto itself in the reality of a professional ballerina.

When a ballerina first unwraps a pair of brand-new pointe shoes, they won’t remain that way for long. To the untrained eye, it seems absurd to sew, step on and scratch a flawless new pair of pink satin pointe shoes. But, achieving that perfect fit is an incredibly individualized process that often entails sewing, super glue, specifications and even arm strength.

Here, PBT Principal Christine Schwaner shares her tricks for perfecting her pointe shoes.

Christine Schwaner, PBT Principal Dancer

Current Pointe Shoe Style: Freed Maltese Cross, Size 4.5

First Pair of Pointe Shoes: A Brazilian pointe shoe followed by Chacott’s, her first pair of pointe shoes in the U.S.

Design Customizations: Longer vamp (length from toe to opening of shoe), an arc-shaped side cut, higher heel extension (to keep the shoe on the foot)

Pointe Shoe Rotation: 2 pairs of prepared pointe shoes with 4-5 new pairs a week

Tools of the Trade: Hot glue, scissors, hand-sewn ribbons & elastic, Ouch Pouch toe pads

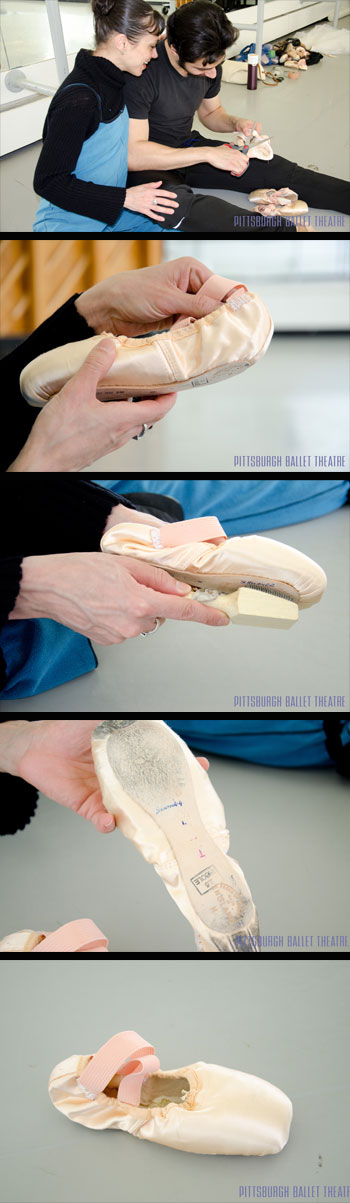

Although pointe shoe preparations are an extremely personal process, PBT Principal Christine Schwaner does entrust one important step to her husband, PBT Soloist Alexandre Silva.

Since she orders shoes with the hardest shank – or sole – strength available, Schwaner calls on her husband to contribute some arm strength. With her guidance, he cuts the shank where it hits the arch of her foot to make sure “the point breaks in the right spot.”

Before cutting, Schwaner usually preps each pair with some hot glue in the toe to extend the life of the shoe. Schwaner finishes up by sewing elastics into her ribbons for performances, and banging the box of the shoes on a hard surface to muffle tapping.

“It’s very time consuming,” she said. “I don’t remember watching TV without having a pointe shoe in my hand.”

Schwaner’s perfect pointe shoe came with the help of a visiting representative from Freed, who gave her a one-on-one fitting at PBT.

“She personalized the pointe shoes. That was a bonus,” she said. “I think pointe shoes are just beautiful. It still amazes me that how we train ourselves to go on the tiptoe of the foot…how graceful you have to be.”

For Schwaner, the pointe shoe acts in tandem with the costumes, makeup and choreography onstage.

“It’s all involved to build the role,” she said. “The pointe shoe, for me, is like the floor. It’s your partner as well. You count on that…I need to have that connection. It’s become very personal that way….Once they’re good to me, I’m very loyal.”

The Perfect Fit: How Alexandra Kochis Breaks in her Pointe Shoes

When a ballerina unwraps a shiny new pair of pointe shoes, they won’t stay that way for long. To the untrained eye, it seems absurd to sew, step on and scratch a satiny pair of $80+ shoes. But for a ballerina, finding the perfect pointe shoe is a Cinderella story of sorts. It starts with choosing a style and manufacturer, like Freed, Capezio or Gaynor Minden, that fits the shape of her foot. Next, comes some DIY refinement. Each ballerina must figure out how to break in her pointe shoes to customize her fit and support her personal dancing style. It’s an incredibly individualized process that often entails sewing, super glue and even arm strength. Here, PBT Principal Dancer Alexandra Kochis takes us through her process.

Alexandra Kochis, PBT Principal dancer

Current Pointe Shoe Style: Freeds, Maker U, Size 4

First Pair of Pointe Shoes: Capezio Contempras, Size 1c

Retired Pointe Shoes: Average 50 pairs a season

Order Specifications:

-No X (for narrow width)

-Size 4 with heel pin (to make them ¼ size bigger)

-Sides cut down (to show the shape of the foot)

-Elastic drawstring and U-shaped vamp

Tools of the Trade: Shellac, superglue, blue handy wipes, construction-strength tin snips, needle & crochet thread, hand-sewn flexer ribbons

Organization System: Kochis names each pair in alphabetized order based on different themes (fruit, candy, etc.)

Somewhere in London, at the Freed pointe shoe factory, there is a maker who hand crafts each pair of Alexandra Kochis’ Maker U pointe shoes.

“It’s a really old-school industry; it’s sort of a labor of love,” Kochis said of the traditionally hand-made craft, which requires six-month lead time for ordering.

But despite the personalized care, each time Kochis unwraps a new pair of pointe shoes, they’re likely to vary slightly from other pairs of the same style. That’s why she’s developed her own roughly 10-step process to personally tailor each pair to her exact preferences.

Starting with a basic, stock-strength shanked shoe, Kochis uses utility-strength scissors to cut the shank – or sole of the pointe shoe – where it hits the arch of her foot for flexibility. Kochis then takes up needle and thread to sew elastics to her ribbons and darn around the toe, enclosing the platform with a circle of small stitches. This creates resistance and keeps her evenly balanced on the box of her shoes.

“It evens out every pair. It gives me a real platform to work on,” she said.

As her shoes break in from use, Kochis sprays shellac and applies super glue inside the pointe shoe to reinforce high-stress areas.

“I like them soft, so I’ll wear them a lot longer,” she said. “When it’s super hard, I feel kind of out of touch with the floor.”

Leaving the satin on the toe’s platform to wear on its own, Kochis scrapes the bottoms with an old-fashioned cobbler’s leather scraper to make the shoes less slippery. Before sliding in her feet, Kochis wraps her toes in blue handy wipes for padding.

Kochis usually spends an hour a week to break in and maintain a rotation of 12-14 pairs of pointe shoes to choose from for rehearsals and performances. She chooses pointe shoes based on the choreography, going for a softer pair for jumps, for example, and a harder pair for turns.

For now at least, Kochis has achieved her perfect pointe shoe fit. She hasn’t altered her order for nearly 10 years.

“In ballet, your feet are like your hands, you have to be able to have the most tactility and control onstage…your shoe hopefully will be like a natural continuation of your foot…When you have that style…you covet those shoes.”

Here is her process in pictures:

The Perfect Fit: Principals Share Secrets to Pointe Shoe Prep

Dancer: JoAnna Schmidt | Photo: Aimee DiAndrea

A dazzling pointe shoe takes the place of the traditional glass slipper when PBT’s Prince searches fair and wide for his perfect match. Even outside the fairytale, finding the perfect pointe shoe fit is a Cinderella story unto itself in the reality of a professional ballerina. Here, PBT’s three principal ballerinas share their tricks for perfecting their pointe shoes. Read more here: